Our Team of 3D Designers and Engineers Can Help Guide Your Design Process from Concept to Reality.

Mold Design

Bringing Your Imagination to Life

In great design, every option is carefully considered. Each mold shape we make takes into account the complete manufacturing process: starting with chocolate type, ingredients, inclusions, fillings, depositing method, vibration methods, cooling systems, demolding methods, take off belt transportation, packaging infeed, packaging type and shipping methods. Our team of 3D artists and engineers will work with you to bring your imagination to life.

Engineering

Built for performance and longevity

Considering many elements, including rib placement, radii, intersections, shape orientation and drive pin engagement, our engineering team designs and reviews every mold construction layout to incorporate performance and longevity into the architecture of the mold.

Process

Not just a mold process. A manufacturing partner.

Whether you’re a veteran to the mold making process or just starting, we thoroughly understand how to create the right shape, quantity and quality mold depending on your process. We’ll work with your team to understand how to make sure our molds are the last ones you’ll ever need.

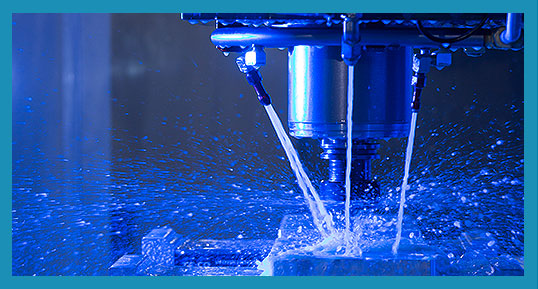

Injection Mold Manufacturing

Beyond Confectionery

Micelli is also able to manufacture molds for displays and packaging such as: Display industry cases for retail brands such as Cosmetics, fragrances, as well as rigid boxes and packaging.

For more information, please contact us about your project.