MICELLI COMPLETES A 24 MONTH PLANT MODERNIZATION AND EXPANSION

Micelli Expands to Ensure Commitment to Future Technology

We recently completed 24-month $2,000,000 plant modernization and expansion as part of our commitment to giving our customers the most efficient manufacturing process possible now, and in the future.

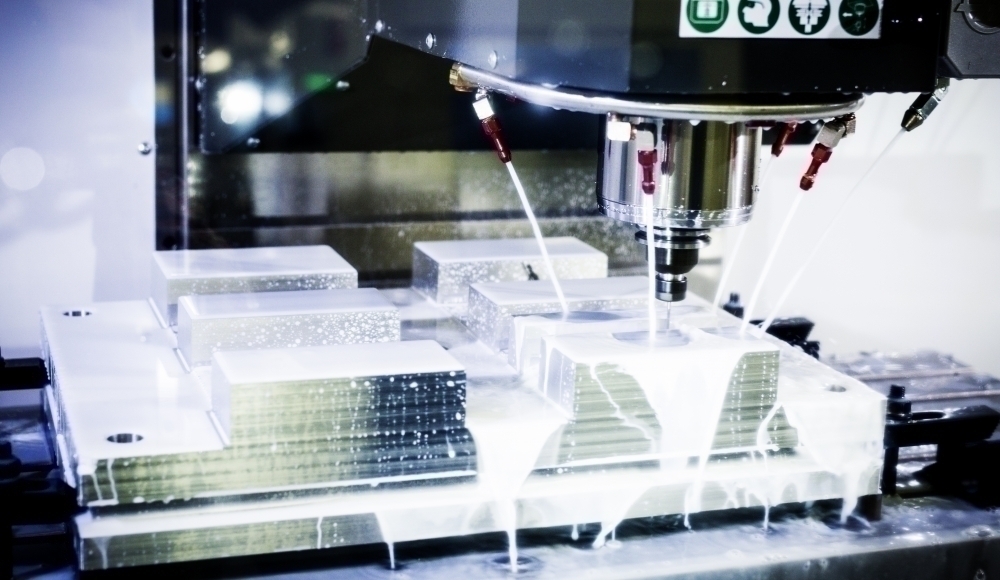

ENGINEERING AND TOOL MAKING CAPABILITIES

The investment includes the addition of an adjacent building which houses a new design and tooling facility. The building contains 5 new engineering workstations and 9 new CNC milling centers. This investment further bolsters our commitment to continuous improvement in the chocolate mold and confectionery related products arena. It also allows expansion of tool making capabilities for non-chocolate products such as displays and automotive components. This diversification allows Micelli to be stronger and continue investments for all of our customer’s needs.

PRODUCTION - TOOLING

We have added to our production master mold tooling as well, adding two additional master mold base/bolster tools. The first is a smaller 1-ton mold base for producing Artisan and smaller sized molds; we are committed to providing our Artisan customers the same quality and service, as we have been known for in the industrial market. The second is a 5-ton master mold base for industrial sized chocolate molds that allow improved quality and efficiency.

PRODUCTION - INJECTION MOLDING

Our production facility has been upgraded with new power systems and two additional injection-molding presses. The first is a smaller sized press with robotic operation to produce complementary products for both confectionery and non-confectionery related items. The second is a brand new large injection molding press for large molds and oversized parts. This adds to our existing 4 presses making a total of 6 presses in the facility.