The Evolution of Chocolate Molding

From Artisan Craftsmanship to Industrial Precision

Chocolate molding has a rich history that bridges the gap between traditional artistry and modern technology. For centuries, chocolatiers have used molds to create intricate designs and unique shapes that delight consumers. Artisan chocolatiers rely on molds as a canvas for their creativity, crafting products that tell a story. Meanwhile, industrial manufacturers leverage molds to meet the demands of mass production while maintaining quality and precision.

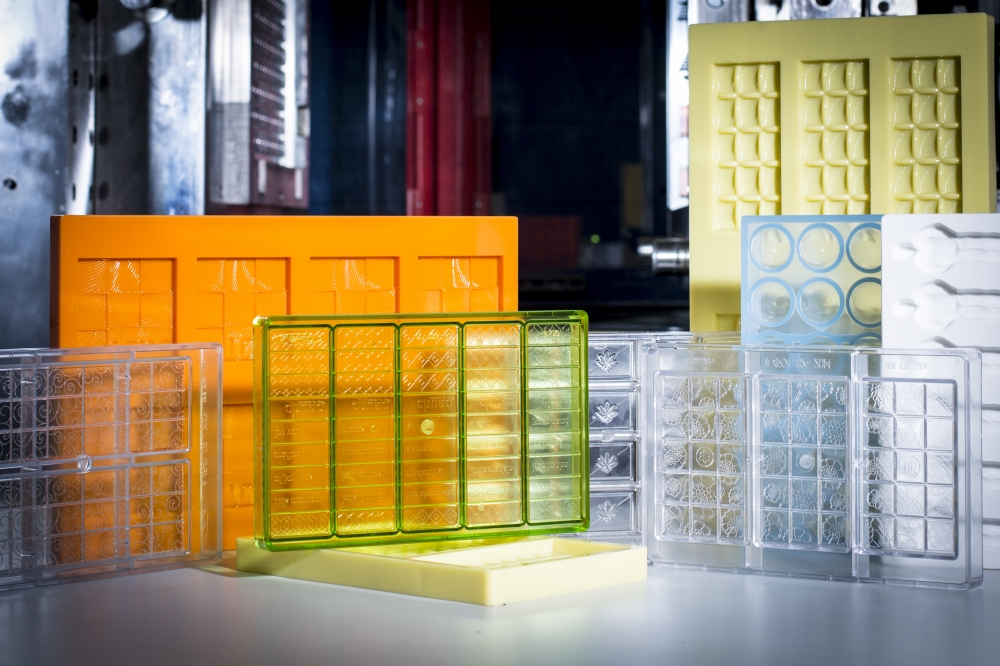

Micelli Chocolate Molds sits at the intersection of these two worlds. By offering polycarbonate injection molds, Micelli provides tools that empower both artisan and industrial chocolatiers to achieve their goals. These molds are not only durable but also allow for intricate designs that elevate chocolate products. For artisan chocolatiers, this means crafting standout pieces that compete on quality and aesthetics. For industrial players, it means efficiency and consistency at scale.

Today, as consumer preferences evolve, the importance of advanced molding techniques has grown. Customers expect chocolates that not only taste exquisite but also look flawless. Whether it’s a single artisan shop or a large-scale manufacturer, choosing the right molds can significantly impact product success. Micelli’s innovative approach ensures that chocolatiers of all scales can meet these expectations while staying true to their brand identities.

By bridging tradition with innovation, Micelli continues to set the standard for chocolate molding. Their expertise in polycarbonate injection molds ensures that every chocolatier—whether crafting by hand or running a factory line—has the tools to create something extraordinary