Scaling Your Chocolate Production

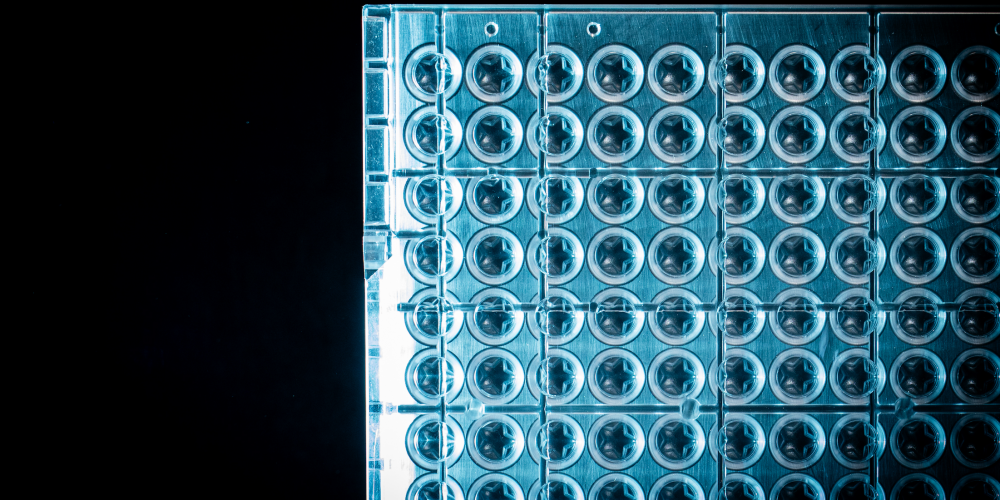

How Industrial-Grade Molds Benefit High-Volume Cannabis Chocolatiers

Micelli Chocolate Molds

As the cannabis confectionery industry grows, high-volume production is becoming increasingly important. Industrial-grade molds from Micelli Chocolate Molds provide the durability and precision needed to scale operations without sacrificing quality.

How Micelli Empowers Small-Scale Producers

Supporting Artisan Chocolatiers

Micelli Chocolate Molds

Artisan chocolatiers bring passion and creativity to every piece they create. At Micelli Chocolate Molds, we are dedicated to supporting these small-scale producers by providing molds that enhance their craft and help them thrive in a competitive market.

The Sweet Success of Coblentz Chocolates

From Farm Roots to Family Brands

Micelli Chocolate Molds

At its core, Coblentz has always been about connection. Not just between chocolate and consumer—but between business and community, employer and employee, tradition and innovation.

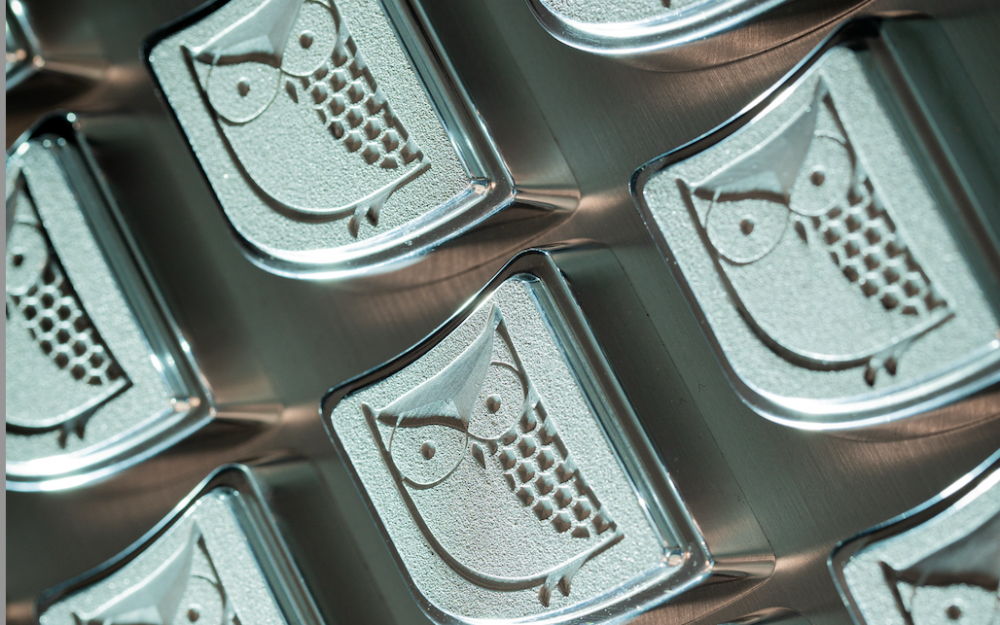

Customization in Chocolate Molding

Tailoring Designs for Artisan and Industrial Needs

Micelli Chocolate Molds

Customization is key in today’s chocolate market. Consumers are drawn to unique products that stand out, whether it’s a hand-crafted truffle or a branded chocolate bar. Micelli Chocolate Molds recognizes this demand and specializes in creating custom molds that cater to the specific needs of artisan and industrial chocolatiers alike.

The Evolution of Chocolate Molding

From Artisan Craftsmanship to Industrial Precision

Chocolate molding has a rich history that bridges the gap between traditional artistry and modern technology. For centuries, chocolatiers have used molds to create intricate designs and unique shapes that delight consumers. Artisan chocolatiers rely on molds as a canvas for their creativity, crafting products that tell a story. Meanwhile, industrial manufacturers leverage molds to meet the demands of mass production while maintaining quality and precision. Micelli Chocolate Molds sits at the intersection of these two worlds.

For The Love of Making Chocolate: Micelli Interviews Birmingham Chocolate

Birmingham Chocolate Offers Delightful Chocolate Treats With All-Natural Flavors

Birmingham Chocolate started out as a chocolateria in their neighborhood of Birmingham, Michigan and today they’re delighting their customers with uniquely flavored chocolate bars and artfully crafted bonbons and treats.

In our interview we learned why they’re reinventing their business, shifting from a brick-and-mortar to a digital storefront where their delicious chocolates are available with the click of a button. This chocolateria takes artistry to new heights and truly elevates the experience of enjoying fine chocolate.

Read on to learn more about Birmingham Chocolate!

For The Love of Making Chocolate: Micelli Interviews Woodblock Chocolate

Woodblock Chocolate’s Passion for Craft Chocolate Comes Through In Each of Their Delicious Creations

This family-run chocolate manufactory located in Portland, Oregon is run by wife and husband team Jessica and Charley Wheelock. Their passion for craft chocolate sent them on a journey towards understanding and perfecting every step of the bean-to-bar process – and all that had work really paid off.

Read our interview below and learn about the goings-on at their spacious Manufactory – where all of their delicious craft chocolate is produced.

Keep reading to discover more about Woodblock Chocolate.

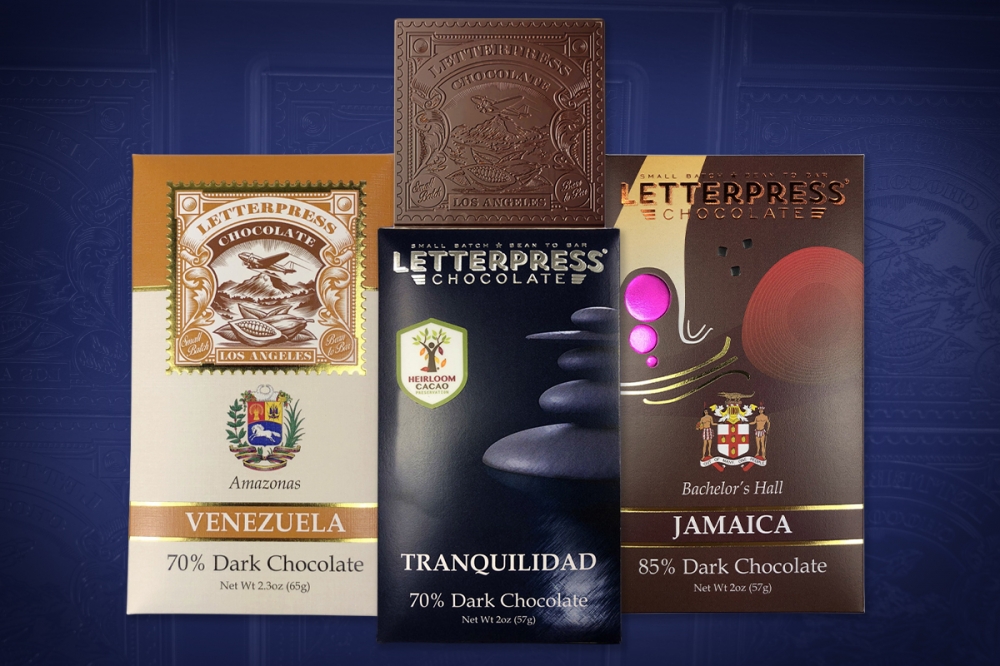

For The Love of Making Chocolate: Micelli Interviews Letterpress Chocolate

Letterpress Chocolate Puts Care Into Every Step Of Their Bean-To-Bar Process

This small bean-to-bar chocolate company produce their bars with the highest quality ingredients for a rich flavorful payoff. Owners David and Corey Menkes handle the entire process themselves, starting with sourcing the best cacao beans they can find.

They are the first bean-to-bar company to emerge in Los Angeles, California and have been introducing customers to their small-batch chocolate bars since 2014. Crafting their chocolate on a very small scale means they can take the time to produce the type of quality you won’t find in industrial brands.

Read our interview to find out more about Letterpress Chocolate!

For The Love of Making Chocolate: Micelli Interviews Dick Taylor Chocolate

While we are well equipped to bring even the wildest imaginations to life, we are continuously impressed and inspired by the ideas our clients bring to us to execute.

When founders Adam Dick and Dustin Taylor of Dick Taylor Chocolate came to us, we knew it was not innovation, but tradition, that drove this duo to create.

When they got their start, they were fueled by the desire to disrupt the mass produced chocolate bar industry with a focus on high quality ingredients that enhance the rich flavor of the chocolate.

Read the full interview here and learn why Dick Taylor Chocolate changing the “bean to bar” game.