For The Love of Making Chocolate: Micelli Interviews Dick Taylor Chocolate

Learn From The Tradition of Dick Taylor Chocolate

While we are well equipped to bring even the wildest imaginations to life, we are continuously impressed and inspired by the ideas our clients bring to us to execute.

When founders Adam Dick and Dustin Taylor of Dick Taylor Chocolate came to us, we knew it was not innovation, but tradition, that drove this duo to create.

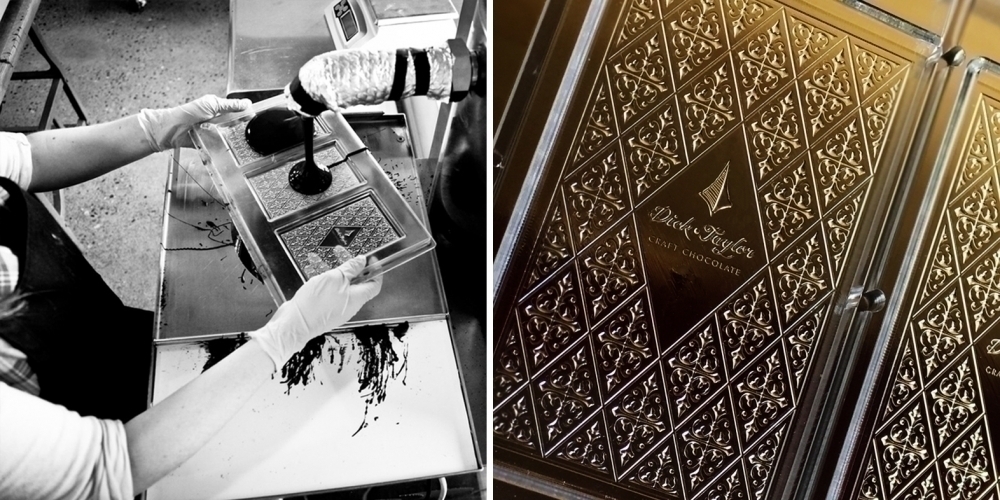

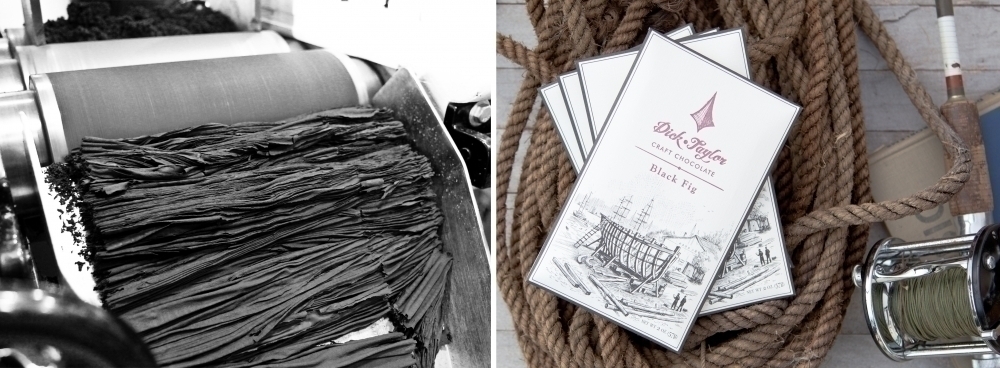

Dick Taylor Chocolate creates craft chocolate from “bean to bar”. Founders, Adam Dick and Dustin Taylor, have been crafting all their lives. What started in wood furniture eventually evolved into an artisan chocolate brand with high standards and traditional machinery.

Based in Eureka, CA, this duo began by sourcing the finest, fair trade, raw cacao they could get their hands on. With a distinctive focus on organic ingredients and distinguishable design, Dick Taylor Chocolate sets the bar high for craft chocolate. When they got their start, they were fueled by the desire to disrupt the mass produced chocolate bar industry with a focus on high quality ingredients that enhance the rich flavor of the chocolate.

Attracted to a process that had been long forgotten by the industry as a whole, the duo decided to take chocolate making back to the roots and hand-selected production machines based on tradition rather than modernity.

Their two-ingredient, single origin dark chocolate is some of the highest quality craft chocolate you can find. We are honored to supply their custom polycarbonate injection molds and just had to learn more about where they came from and where this journey is taking them into the future.

Do you plan to scale up your production?

Yes. As the world of craft chocolate continues to gain momentum, we plan on growing with it. With that growth comes new equipment and new employees to keep up with demand.

What motivated you to start making chocolate?

We have always had a passion for working with our hands. Chocolate making has allowed us to live that passion everyday, whether it is rebuilding the machinery used in the factory, or making, molding, & packaging the bars themselves.

How did you get the idea of making chocolate?

For as long as we have known each other, we have always been searching out new hobbies. We happened upon a video on YouTube about bean to bar chocolate making, we were intrigued by all of the steps and effort it took to make a two ingredient chocolate bar.

How has Micelli Molds helped you in the chocolate making process?

The high quality polycarbonate injection molds allow us to carry our branding all the way through the finished chocolate bar. The quality of the mold itself gives us confidence that every bar molded will look flawless and exactly how we desire it to look. The durability of the molds has allowed us to increase production without having to replace the molds themselves.

What is the best part of working with chocolate?

The best part of making chocolate is the broad spectrum of people it has brought into our lives. From cacao farmers, artisan vendors, other chocolate makers, and customers worldwide, we have been able to share the passion we have for chocolate. There is nothing more rewarding than hearing responses from people who take joy in the products we are making, and feel inspired by what we are doing.

Why is it important to your brand to use such an intricate design directly on the bar of chocolate?

It allows the bar itself to represent the high quality and elegance that is bean to bar craft chocolate. When someone sees our bar for the first time, they know that there was thoughtfulness put into the chocolate because of the thoughtfulness that went into the mold. Additionally, it helps our bars stand out from the other makers and is recognizable. If you were to see our bar with no packaging, it is very obvious that it is a Dick Taylor bar.

We look forward to watching Dick Taylor Chocolate inspire the next generation of chocolate lovers with their ceaseless ingenuity and genuine fortitude.

For the love of making chocolate,

The Micelli Team