Beyond the Bunny

Custom Seasonal Chocolate Molds

Micelli Chocolate Molds

In the world of confectionery, holidays are more than just dates on a calendar - they are the busiest and most profitable times of the year. From the Cupid’s bows at Valentine’s Day to Santa’s reindeer at Christmas, seasonal sales drive the industry.

Quality Assurance in Chocolate Molding

Ensuring Consistency Across Batches

Micelli Chocolate Molds

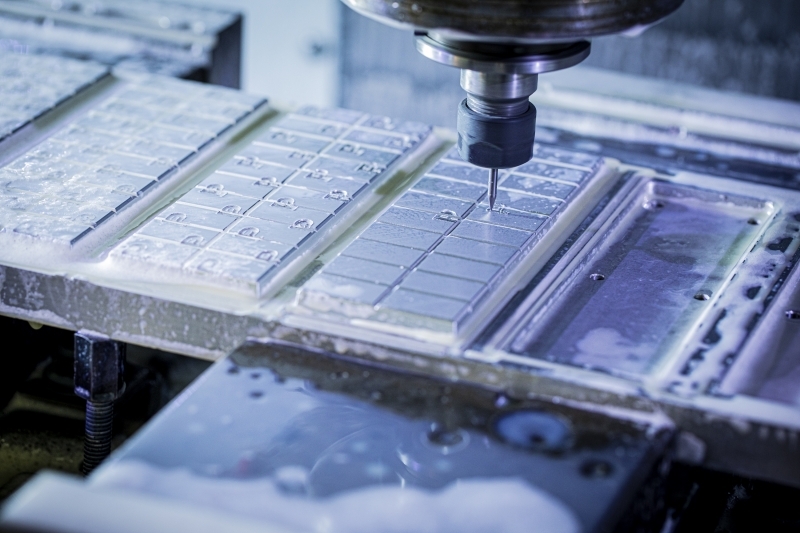

Consistency is king in chocolate production, and high-quality molds are essential to achieving it. At Micelli Chocolate Molds, we prioritize quality assurance to ensure that every mold we produce meets the highest standards.

The Artisan's Guide to Building the Right Chocolate Mold

Our Chocolate Molds Fit Your Unique Needs

Micelli Chocolate Molds

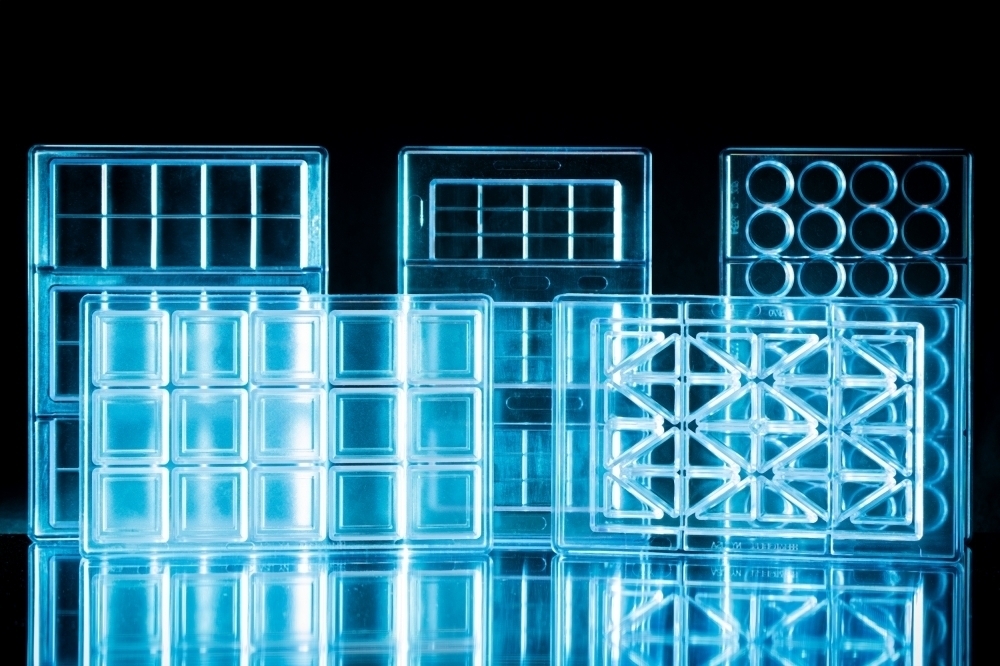

Selecting the right mold is one of the most critical decisions an artisan chocolatier can make. A well-chosen mold not only enhances the quality of the finished product but also streamlines the production process. At Micelli Chocolate Molds, we understand the unique needs of artisan chocolatiers and offer a diverse range of options to suit any production style.

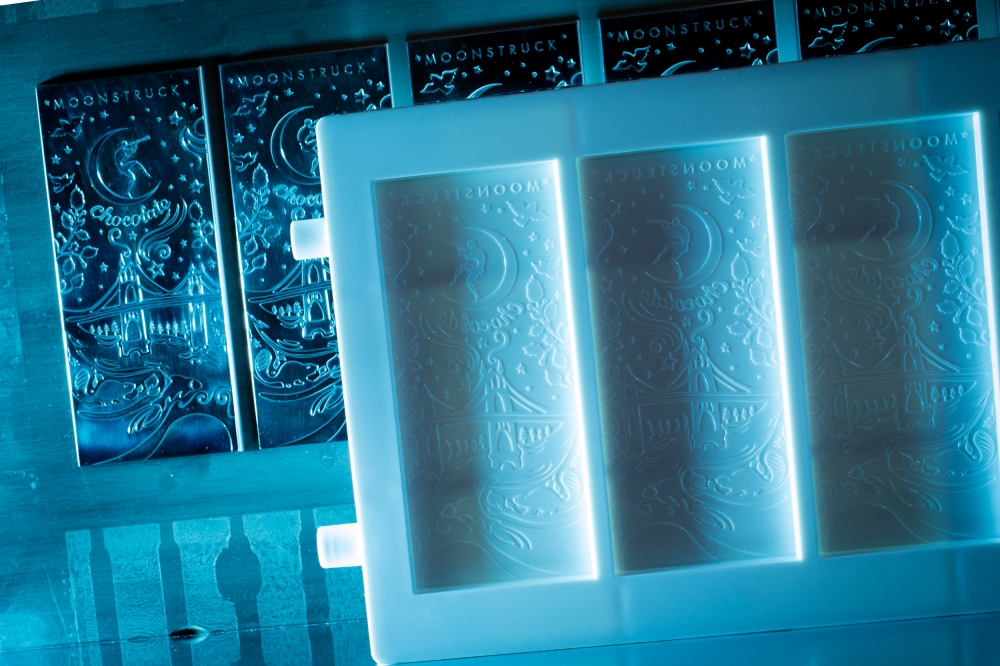

Customization in Chocolate Molding

Tailoring Designs for Artisan and Industrial Needs

Micelli Chocolate Molds

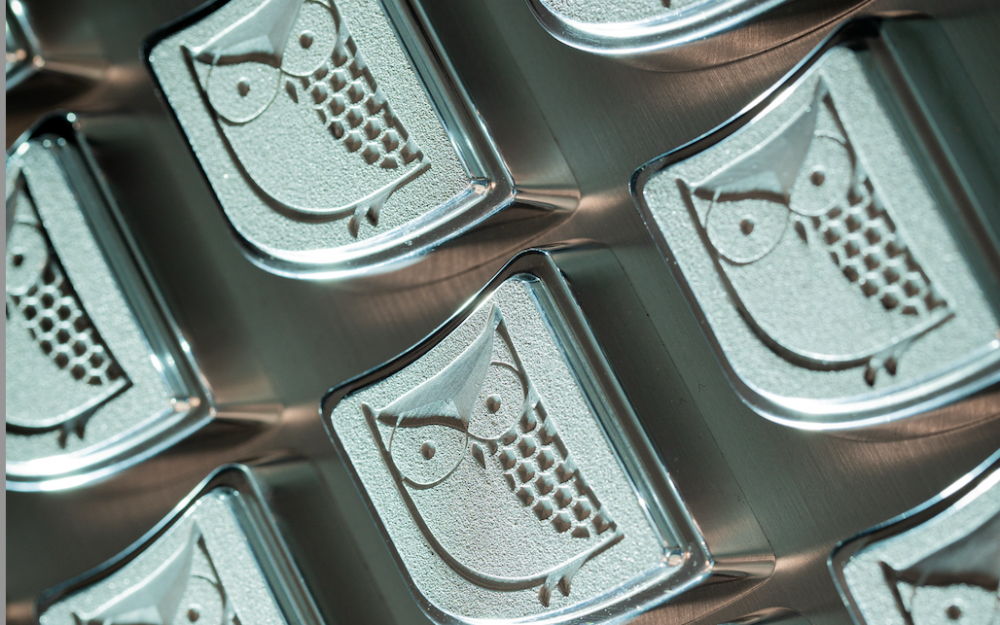

Customization is key in today’s chocolate market. Consumers are drawn to unique products that stand out, whether it’s a hand-crafted truffle or a branded chocolate bar. Micelli Chocolate Molds recognizes this demand and specializes in creating custom molds that cater to the specific needs of artisan and industrial chocolatiers alike.

The Role of Innovation in Chocolate Mold Manufacturing

Micelli's Approach Delivers Results

Micelli Chocolate Molds

Innovation is at the heart of Micelli Chocolate Molds’ success. As consumer tastes and industry standards evolve, so too must the tools chocolatiers use to create their products.

Enhancing Production Efficiency with High-Quality Industrial Chocolate Molds

A Trusted Partner For Industrial Chocolatiers

Micelli Chocolate Molds

Efficiency is everything in the industrial chocolate production process. High-quality molds not only speed up manufacturing but also ensure consistency, reducing waste and improving overall output. Micelli Chocolate Molds is a trusted partner for industrial chocolatiers seeking to optimize their operations.

Bissinger’s: A Legacy of Chocolate, Reinvented

Micelli Interviews Bissinger's Handcrafted Chocolates

Micelli Chocolate Molds

In a world of fleeting trends and fast flavors, Bissinger’s Chocolatier is a brand rooted in something far richer—legacy. But legacy doesn’t mean stagnant. If anything, it’s been a launchpad for innovation, reinvention, and a whole lot of sweet surprises.

Navigating the Future Of Chocolate

Trends in Chocolate Molding for 2025 and Beyond

Micelli Chocolate Molds

The chocolate industry is constantly evolving, driven by changing consumer preferences and technological advancements. Micelli Chocolate Molds is at the forefront of these changes, helping chocolatiers navigate the future with innovative mold solutions.

Sustainable Chocolate Production

How Quality Molds Reduce Waste and Enhance Efficiency

Sustainability is more than a buzzword—it’s a necessity in today’s chocolate industry. As consumers demand eco-friendly practices, chocolatiers must adapt their operations to reduce waste and improve efficiency. One often-overlooked aspect of sustainability is the role of high-quality molds.

Why Polycarbonate Injection Molds are the Gold Standard for Chocolatiers

Your Choice Of Mold Can Make Or Break A Product

In the world of chocolate production, the choice of mold can make or break a product. Polycarbonate injection molds have become the gold standard for chocolatiers, and for good reason.

The Evolution of Chocolate Molding

From Artisan Craftsmanship to Industrial Precision

Chocolate molding has a rich history that bridges the gap between traditional artistry and modern technology. For centuries, chocolatiers have used molds to create intricate designs and unique shapes that delight consumers. Artisan chocolatiers rely on molds as a canvas for their creativity, crafting products that tell a story. Meanwhile, industrial manufacturers leverage molds to meet the demands of mass production while maintaining quality and precision. Micelli Chocolate Molds sits at the intersection of these two worlds.

Micelli Acquires Aztec Tool Company

The acquisition expands services while consolidating chocolate and confectionaries mold-building under the Micelli name.

Micelli + Aztec

West Babylon, NY, based Micelli Chocolate Mold Company (micelli.com) is pleased to announce the acquisition of Edgewood, NY, based Aztec Tool Company, Inc (aztectool.com). The purchase expands Aztec’s growing commercial and industrial toolmaking and plastic injection molding capabilities, while Micelli refocuses exclusively on its chocolate, confections and related markets. Aztec Tool Company has been renamed and rebranded Aztec Tooling & Injection Molding Company to reflect its expanded capabilities, complete with new logo design.

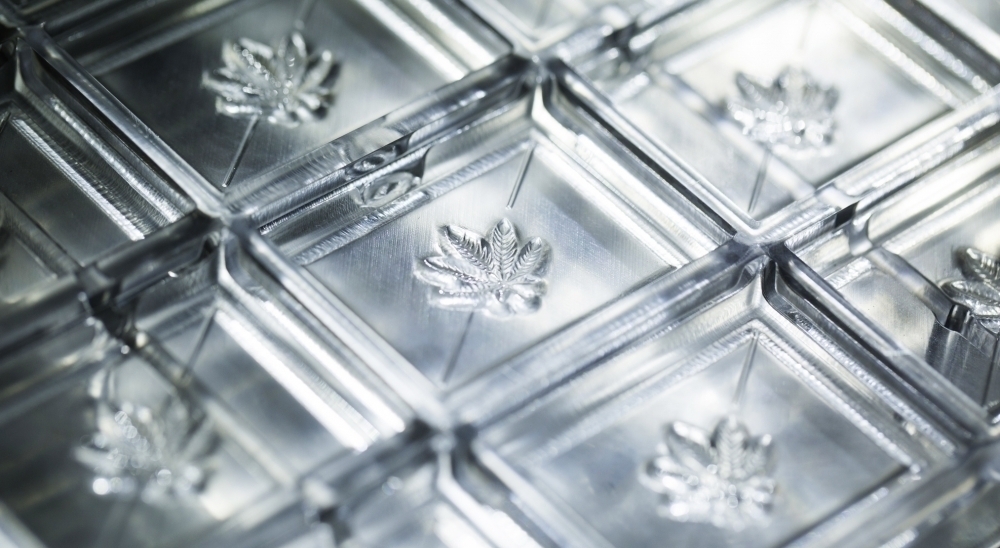

For The Love of Making Chocolate: Micelli Interviews Kiva Confections

Kiva Confections, based in Oakland, California, creates cannabis infused artisan chocolates that serve patients looking for alternative ways of consuming their medicinal cannabis. Their dedication to efficiency, safety, and quality make them the leader in a progressive, burgeoning market.

In 2010, Founders Scott Palmer and Kristi Knoblich set out to become pioneers in the medicinal cannabis market by meticulously crafting some of California’s most highly regarded edibles. Their market requires a high degree of accuracy, consistency, and definition - a perfect challenge for the precision and craft of Micelli's polycarbonate injection molds. The fine ingredients and skillful craft to making their chocolates mirrors the integrity of Kiva Confections– to produce quality products that promote quality treatment.

Recently, we reached out to our friends at Kiva Confections to understand how they have found their sweet-spot in a budding industry.

Read Our Entire Interview

For The Love of Making Chocolate: Micelli Interviews Art Pollard from Amano Artisan Chocolate

Art Pollard, founder of Amano Artisan Chocolate, is a hands-on kind of guy with a keen eye for quality and a passion for connecting with farmers and getting to the source of the bean. He travels the world looking for the highest quality cacao beans and searching for the farmers that grow with their hearts.

Based in Utah’s Wasatch Mountain range in the heart of the Rockies, Amano is dedicated to creating some of the world’s most exquisite chocolate through traditional techniques. “Amano means ‘by hand’ and ‘they love’ in Italian, and that describes the care and perfection that Amano brings to chocolate and in turn to the people who savor it.”

Pollard visits plantations, forms deep and long-lasting relationships with farmers, and even helps them improve their processes to raise the standard of their cacao beans.

Recently, we sat down with Art Pollard of Amano Artisan Chocolate to discover how he got his start and what drives him to continue searching the world for the best cacao.

Read Our Entire Interview

For The Love of Making Chocolate: Micelli Interviews Dick Taylor Chocolate

While we are well equipped to bring even the wildest imaginations to life, we are continuously impressed and inspired by the ideas our clients bring to us to execute.

When founders Adam Dick and Dustin Taylor of Dick Taylor Chocolate came to us, we knew it was not innovation, but tradition, that drove this duo to create.

When they got their start, they were fueled by the desire to disrupt the mass produced chocolate bar industry with a focus on high quality ingredients that enhance the rich flavor of the chocolate.

Read the full interview here and learn why Dick Taylor Chocolate changing the “bean to bar” game.

MOLDING THE FUTURE

Molds for Cannabis Edibles

We're helping the pioneers of the quickly emerging medicinal cannabis-edibles industry bring their products to market.

MICELLI’S SUCCESS IN CONFECTIONERY MOLDS OPENS DOORS IN THE RETAIL DISPLAY MOLD MARKET

The chocolate Mold business requires a company to be proficient in many areas such as engineering, tool manufacturing, and injection molding. It requires a company set up for quick turn around and short run injection molding.

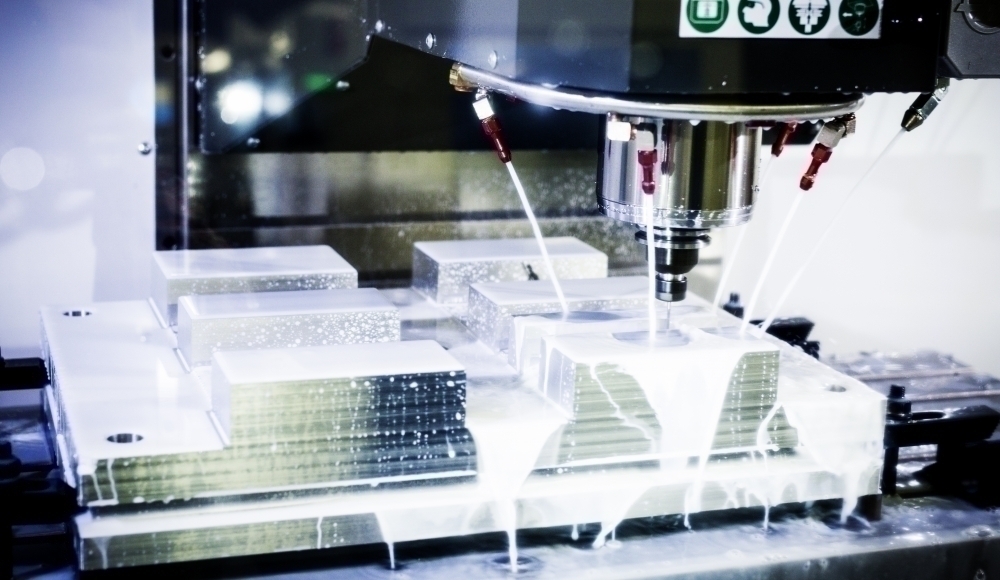

MICELLI COMPLETES A 24 MONTH PLANT MODERNIZATION AND EXPANSION

We recently completed 24-month $2,000,000 plant modernization and expansion as part of our commitment to giving our customers the most efficient manufacturing process possible now and in the future.