Scaling Your Chocolate Production

How Industrial-Grade Molds Benefit High-Volume Cannabis Chocolatiers

Micelli Chocolate Molds

As the cannabis confectionery industry grows, high-volume production is becoming increasingly important. Industrial-grade molds from Micelli Chocolate Molds provide the durability and precision needed to scale operations without sacrificing quality.

Quality Assurance in Chocolate Molding

Ensuring Consistency Across Batches

Micelli Chocolate Molds

Consistency is king in chocolate production, and high-quality molds are essential to achieving it. At Micelli Chocolate Molds, we prioritize quality assurance to ensure that every mold we produce meets the highest standards.

The Sweet Success of Coblentz Chocolates

From Farm Roots to Family Brands

Micelli Chocolate Molds

At its core, Coblentz has always been about connection. Not just between chocolate and consumer—but between business and community, employer and employee, tradition and innovation.

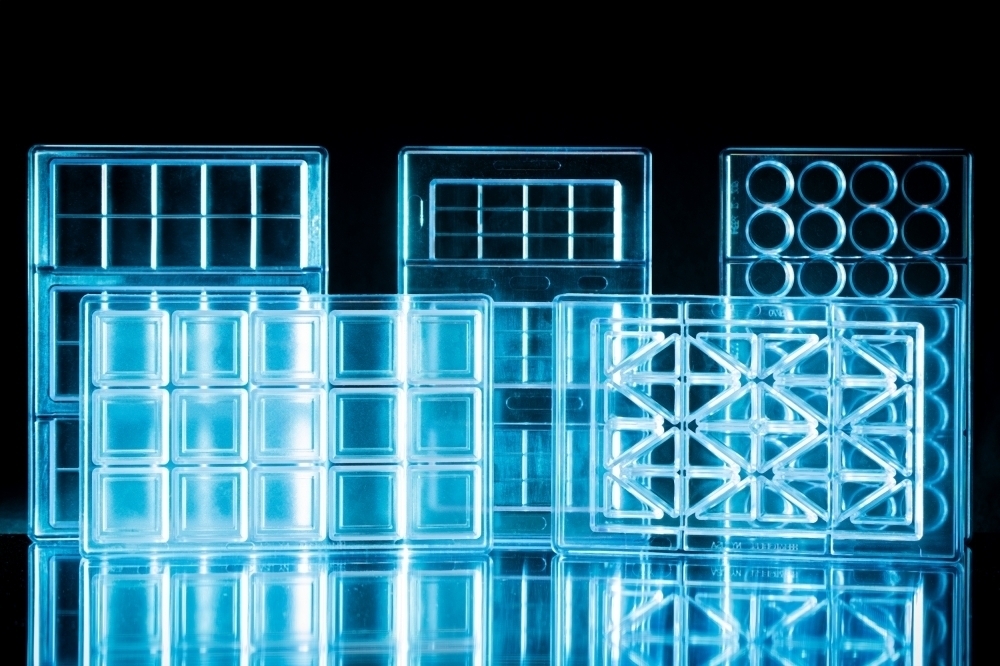

The Artisan's Guide to Building the Right Chocolate Mold

Our Chocolate Molds Fit Your Unique Needs

Micelli Chocolate Molds

Selecting the right mold is one of the most critical decisions an artisan chocolatier can make. A well-chosen mold not only enhances the quality of the finished product but also streamlines the production process. At Micelli Chocolate Molds, we understand the unique needs of artisan chocolatiers and offer a diverse range of options to suit any production style.

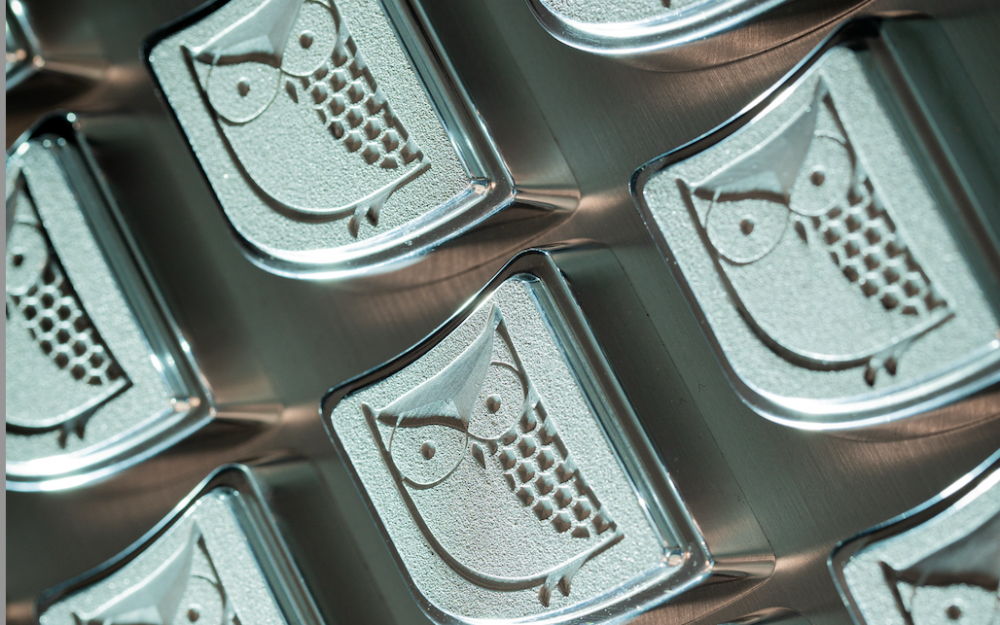

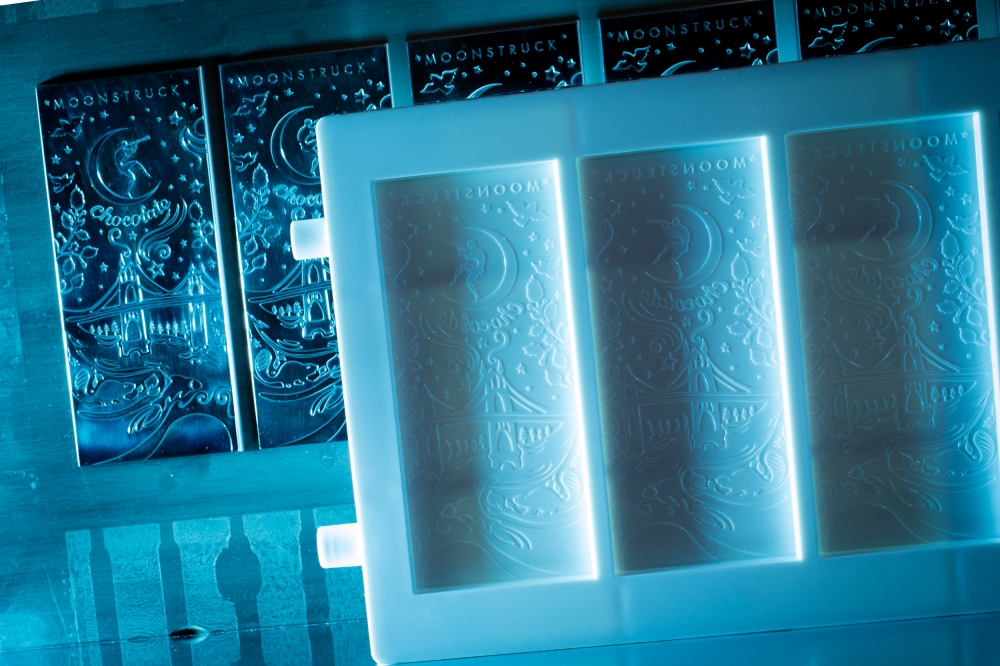

Customization in Chocolate Molding

Tailoring Designs for Artisan and Industrial Needs

Micelli Chocolate Molds

Customization is key in today’s chocolate market. Consumers are drawn to unique products that stand out, whether it’s a hand-crafted truffle or a branded chocolate bar. Micelli Chocolate Molds recognizes this demand and specializes in creating custom molds that cater to the specific needs of artisan and industrial chocolatiers alike.

The Role of Innovation in Chocolate Mold Manufacturing

Micelli's Approach Delivers Results

Micelli Chocolate Molds

Innovation is at the heart of Micelli Chocolate Molds’ success. As consumer tastes and industry standards evolve, so too must the tools chocolatiers use to create their products.

Enhancing Production Efficiency with High-Quality Industrial Chocolate Molds

A Trusted Partner For Industrial Chocolatiers

Micelli Chocolate Molds

Efficiency is everything in the industrial chocolate production process. High-quality molds not only speed up manufacturing but also ensure consistency, reducing waste and improving overall output. Micelli Chocolate Molds is a trusted partner for industrial chocolatiers seeking to optimize their operations.

The Cannabis Confectionery Revolution

How Precision Molds Enhance THC Chocolate Production

Micelli Chocolate Molds

The cannabis confectionery market is rapidly expanding, and THC-infused chocolates are a significant driver of this growth. As cannabis consumers demand more sophisticated and professional products, chocolatiers are turning to high-quality molds to meet these expectations. Precision molds play a crucial role in creating consistent, visually appealing, and accurately dosed cannabis-infused chocolates.

Bissinger’s: A Legacy of Chocolate, Reinvented

Micelli Interviews Bissinger's Handcrafted Chocolates

Micelli Chocolate Molds

In a world of fleeting trends and fast flavors, Bissinger’s Chocolatier is a brand rooted in something far richer—legacy. But legacy doesn’t mean stagnant. If anything, it’s been a launchpad for innovation, reinvention, and a whole lot of sweet surprises.

Navigating the Future Of Chocolate

Trends in Chocolate Molding for 2025 and Beyond

Micelli Chocolate Molds

The chocolate industry is constantly evolving, driven by changing consumer preferences and technological advancements. Micelli Chocolate Molds is at the forefront of these changes, helping chocolatiers navigate the future with innovative mold solutions.

Sustainable Chocolate Production

How Quality Molds Reduce Waste and Enhance Efficiency

Sustainability is more than a buzzword—it’s a necessity in today’s chocolate industry. As consumers demand eco-friendly practices, chocolatiers must adapt their operations to reduce waste and improve efficiency. One often-overlooked aspect of sustainability is the role of high-quality molds.

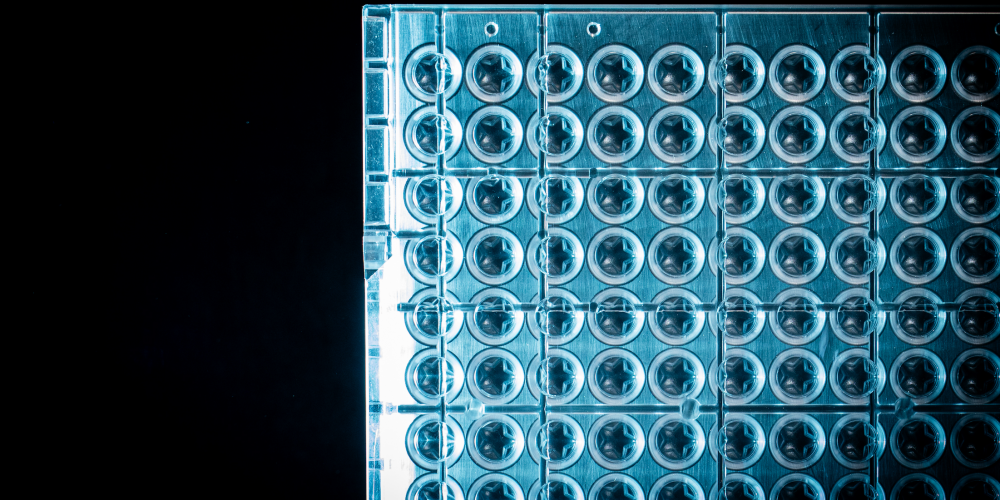

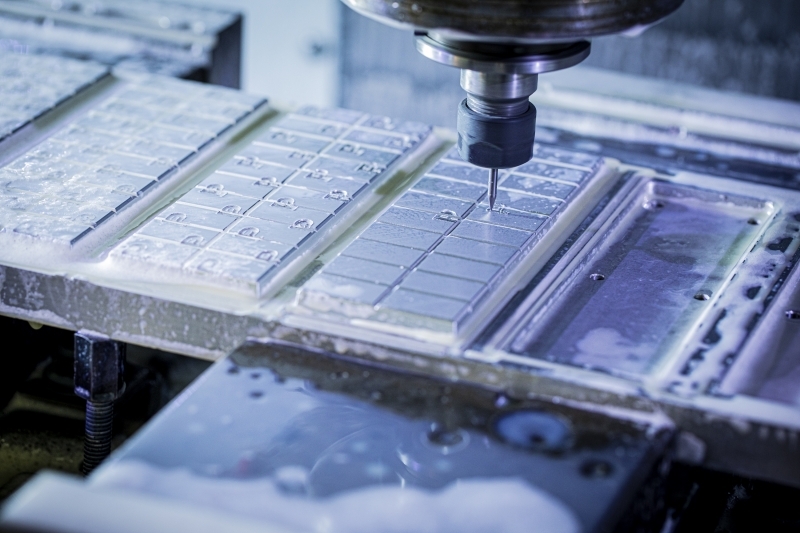

Why Polycarbonate Injection Molds are the Gold Standard for Chocolatiers

Your Choice Of Mold Can Make Or Break A Product

In the world of chocolate production, the choice of mold can make or break a product. Polycarbonate injection molds have become the gold standard for chocolatiers, and for good reason.

The Evolution of Chocolate Molding

From Artisan Craftsmanship to Industrial Precision

Chocolate molding has a rich history that bridges the gap between traditional artistry and modern technology. For centuries, chocolatiers have used molds to create intricate designs and unique shapes that delight consumers. Artisan chocolatiers rely on molds as a canvas for their creativity, crafting products that tell a story. Meanwhile, industrial manufacturers leverage molds to meet the demands of mass production while maintaining quality and precision. Micelli Chocolate Molds sits at the intersection of these two worlds.

For The Love of Making Chocolate: Micelli Interviews Birdsnake Chocolate

Birdsnake Chocolate Does Their Part In Ensuring The Cacao Industry Gets A Fair Go

It’s time for another installment of For the Love of Making Chocolate and this time we got in touch with Fred Lullfitz from Birdsnake Chocolate in Melbourne, Australia. Birdsnake Chocolate is a small craft chocolate brand that started in 2018 and adopts its unique name and standout branding from the Olmec people’s belief in the origin of chocolate.

Their product range runs the gamut from traditional craft chocolate bars to their Strange Magic chocolate spread – all made with cacao sourced from around the globe. Read our full interview below to learn about the driving-force behind their decision to pay above board for their quality cacao.

Read on to learn more about Birdsnake Chocolate!

For The Love of Making Chocolate: Micelli Interviews Birmingham Chocolate

Birmingham Chocolate Offers Delightful Chocolate Treats With All-Natural Flavors

Birmingham Chocolate started out as a chocolateria in their neighborhood of Birmingham, Michigan and today they’re delighting their customers with uniquely flavored chocolate bars and artfully crafted bonbons and treats.

In our interview we learned why they’re reinventing their business, shifting from a brick-and-mortar to a digital storefront where their delicious chocolates are available with the click of a button. This chocolateria takes artistry to new heights and truly elevates the experience of enjoying fine chocolate.

Read on to learn more about Birmingham Chocolate!

Micelli Acquires Aztec Tool Company

The acquisition expands services while consolidating chocolate and confectionaries mold-building under the Micelli name.

Micelli + Aztec

West Babylon, NY, based Micelli Chocolate Mold Company (micelli.com) is pleased to announce the acquisition of Edgewood, NY, based Aztec Tool Company, Inc (aztectool.com). The purchase expands Aztec’s growing commercial and industrial toolmaking and plastic injection molding capabilities, while Micelli refocuses exclusively on its chocolate, confections and related markets. Aztec Tool Company has been renamed and rebranded Aztec Tooling & Injection Molding Company to reflect its expanded capabilities, complete with new logo design.

For The Love of Making Chocolate: Micelli Interviews Woodblock Chocolate

Woodblock Chocolate’s Passion for Craft Chocolate Comes Through In Each of Their Delicious Creations

This family-run chocolate manufactory located in Portland, Oregon is run by wife and husband team Jessica and Charley Wheelock. Their passion for craft chocolate sent them on a journey towards understanding and perfecting every step of the bean-to-bar process – and all that had work really paid off.

Read our interview below and learn about the goings-on at their spacious Manufactory – where all of their delicious craft chocolate is produced.

Keep reading to discover more about Woodblock Chocolate.

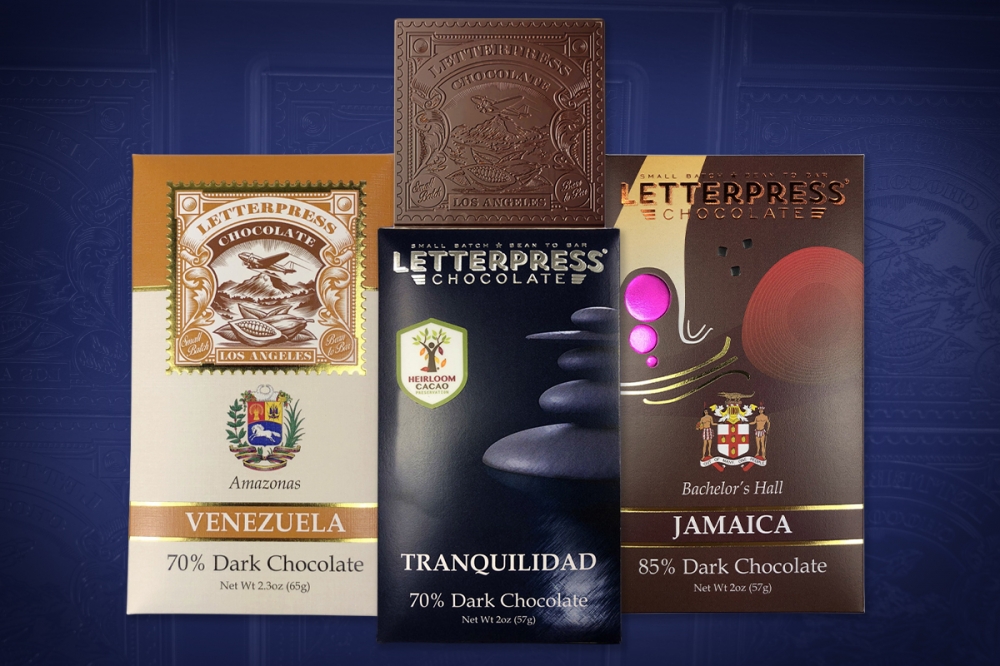

For The Love of Making Chocolate: Micelli Interviews Letterpress Chocolate

Letterpress Chocolate Puts Care Into Every Step Of Their Bean-To-Bar Process

This small bean-to-bar chocolate company produce their bars with the highest quality ingredients for a rich flavorful payoff. Owners David and Corey Menkes handle the entire process themselves, starting with sourcing the best cacao beans they can find.

They are the first bean-to-bar company to emerge in Los Angeles, California and have been introducing customers to their small-batch chocolate bars since 2014. Crafting their chocolate on a very small scale means they can take the time to produce the type of quality you won’t find in industrial brands.

Read our interview to find out more about Letterpress Chocolate!

For The Love of Making Chocolate: Micelli Interviews Ritual Chocolate

MICELLI INTERVIEWS RITUAL CHOCOLATE

It’s time for another installment of For the Love of Making Chocolate. We were able to get in touch with Anna Davies from Ritual Chocolate, an artisan bean-to-bar small batch chocolate company located in Park City, UT. In our interview, we discovered how Ritual Chocolate uses European chocolate-making techniques to elevate the experience of savoring chocolate. We also get into their sustainability efforts. Everything in their process has been thought out in order to maximize the resources available to them. For example, their factory was designed with the natural heat produced by the sun in mind, so they can use this as a heat source of keeping their chocolate melted during production.

Read on to learn more about this mindful and unique chocolate company.

For The Love of Making Chocolate: Micelli Interviews Dick Taylor Chocolate

While we are well equipped to bring even the wildest imaginations to life, we are continuously impressed and inspired by the ideas our clients bring to us to execute.

When founders Adam Dick and Dustin Taylor of Dick Taylor Chocolate came to us, we knew it was not innovation, but tradition, that drove this duo to create.

When they got their start, they were fueled by the desire to disrupt the mass produced chocolate bar industry with a focus on high quality ingredients that enhance the rich flavor of the chocolate.

Read the full interview here and learn why Dick Taylor Chocolate changing the “bean to bar” game.

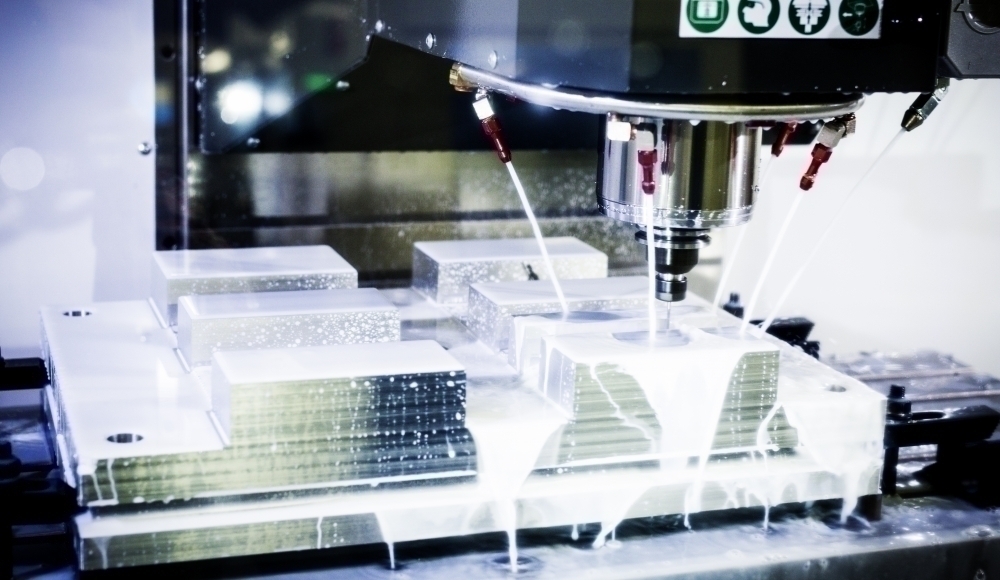

MICELLI COMPLETES A 24 MONTH PLANT MODERNIZATION AND EXPANSION

We recently completed 24-month $2,000,000 plant modernization and expansion as part of our commitment to giving our customers the most efficient manufacturing process possible now and in the future.